Silicones are vital in most Net-Zero Industry Act technologies

The European Commission is set to publish the Net-Zero Industry Act (NZIA) at the end of April. The goal of the act is twofold: increase Europe’s resilience in the manufacturing of net-zero technologies and help deliver on the Fit-for-55 and REPowerEU objectives. Silicones are contributing to both.

Clean technologies in scope of the NZIA: Not without silicones

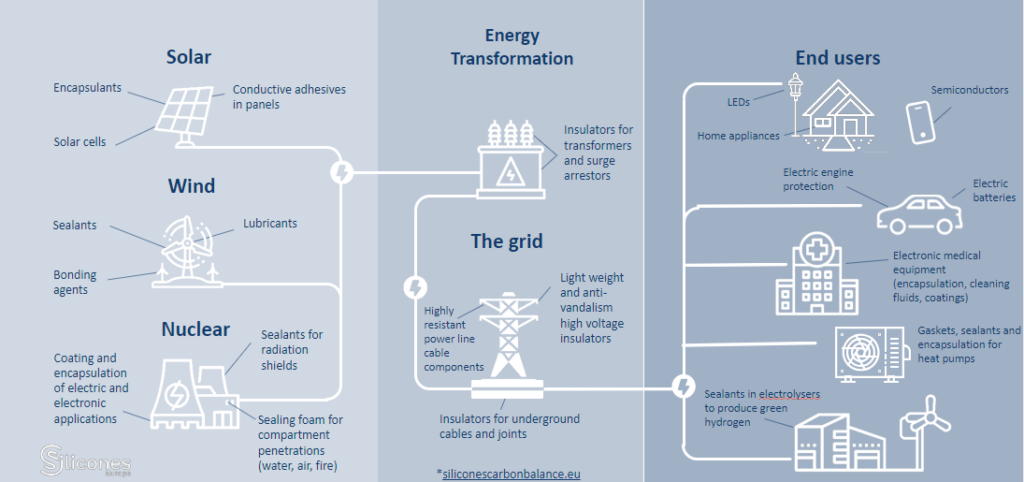

Strategic net-zero technologies within the scope of NZIA include solar power, onshore and offshore renewable energy, battery and storage technologies, heat pumps and geothermal energy, hydrogen, electrolysers and fuel cells, sustainable biogas, carbon capture and storage units, and grid technologies. Silicones are either part and parcel of most of these clean technologies, or required for their manufacture.

In solar power applications, silicones are used during module assembly and installation as encapsulants, coatings, adhesives, and sealants. And the solar cells themselves are made of silicon. For wind turbines advanced adhesives based on silicones are used to bind the giant rotor blades of the wind turbines, and silicone lubricants help minimise the friction in turbine components. Frankly, silicones contribute to the whole energy value chain: from generating energy to end-use applications such as electric vehicles, heatpumps and electrolysers. The picture below speaks louder than words:

In short, not having access to silicones in Europe would impact the development of low-carbon emitting technologies across multiple industries and increase EU dependence on raw materials imports.

Silicone-based applications outperform alternatives when it comes to emission savings

As for the NZIA’s ‘Fit-for-55’ benchmark to reduce EU carbon emissions by 55% by 2030 compared to 1990 levels, silicones are fit for the job. While it is true that silicones production and end-of-life treatment can be energy-intensive, our 2021 carbon balance study revealed that this is more than balanced out during use. For every 1kg of CO2 used to make silicones, you save 14kg by enabling energy saving technologies and a more efficient use of energy and materials.

For instance, the reduction of weight in car parts, leads to fuel and energy saving. Or the improved adhesion of paint to a surface increases the lifetime of the coating, leading to less consumption and therefore production needs. In other words, sustainability benefits to using a silicone-based product over a non-silicone-based product can be attributed to the versatile physical and chemical properties of silicones.

A 2022 study that explored applications of silicones in transportation, construction, electricity, electronics, and manufacturing further confirmed a larger emission-saving potential compared to alternative applications which do not use silicones. In total the emission-saving potential amounts to 96,4 Mt in 2030 for silicone-using technologies. This is equivalent to the carbon footprint of electricity consumption of 36 million persons, almost the number of inhabitants of Poland.

For NZIA to be successful, we need a business case to invest in Europe

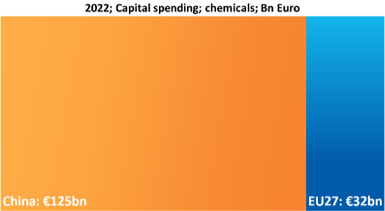

Strategic autonomy in the EU can only be achieved if basic and energy intensive industries remain and invest in Europe. One thing standing in the way of the silicones industry being able to deliver is regulatory uncertainty. European industries need certainty that Europe is an attractive place to put their investments. According to Cefic data, the level of investment in Europe is nearly 4 times less than China.

This is why the chemical industry, together with other industry sectors, have called for a European Industrial Deal which complements the European Green Deal to restore competitiveness and keep good jobs in Europe.